-

What is the corrosion resistance of ETFE anti-corrosion coating sprayed on the mixer

ETFE anti-corrosion coating (commonly known as fluoroplastic coating) is the mainstream treatment solution for corrosion-resistant mixing equipment in industries such as chemical, metallurgical, and environmental protection. ETFE (ethylene tetrafluoroethylene copolymer) itself is a high-performance fluorine material, and the coating combines the corrosion resistance and inertness of fluorine mater

Learn more -

What is the purpose of spraying Xylan coating on bolts

The core function of bolt spraying Xylan coating (a fluoropolymer coating containing polytetrafluoroethylene (PTFE)) is to improve corrosion resistance, lubrication, and wear resistance, while enhancing sealing reliability, solving the problems of corrosion, jamming, and adhesion of bolts under harsh working conditions, extending service life, and reducing maintenance costs. The specific functions

Learn more -

Briefly introduce valve plate spraying ECTFE

Valve plate spraying ECTFE refers to the technology of applying ethylene chlorotrifluoroethylene copolymer (ECTFE) coating on the surface of the valve core component valve plate through professional spraying process, with the aim of improving the comprehensive performance of the valve plate. The following briefly introduces the core advantages, key processes, and main applications:

Learn more -

What are the applications of ETFE anti-corrosion coating for head spraying in the chemical industry

As a key sealing and pressure bearing component of chemical core equipment such as pressure vessels, storage tanks, and reaction vessels, the head is widely used in various strong corrosion conditions in the chemical industry after being sprayed with ETFE coating due to its advantages of strong acid and alkali resistance, high temperature resistance, and high density. It covers multiple core proce

Learn more -

What are the characteristics of PTFE anti adhesive coating sprayed on the material bucket

The material bucket (including mixing bucket, storage bucket, conveying bucket, etc.) is sprayed with PTFE (polytetrafluoroethylene, commonly known as "Teflon") anti adhesive coating. The core is to endow the inner wall of the material bucket with the core characteristics of "lower surface energy+strong stability" through the special molecular structure and spraying process of PTFE material, solvi

Learn more -

What is the purpose of the Xylan coating on the valve stem

Xylan coating is a fluoropolymer coating with polytetrafluoroethylene as the core, which can be applied to the valve stem to solve the problems of wear, corrosion, and jamming of the valve stem under various working conditions. It is suitable for complex use scenarios in multiple industries, and its specific applications are as follows:

Learn more -

What are the advantages of spraying Teflon on lithium battery silos

The core advantages of spraying Teflon on lithium battery silos are anti sticking and anti blocking, anti-corrosion and wear-resistant, ensuring material purity, and adapting to the storage and transportation needs of lithium battery positive and negative electrode powders (such as ternary materials and lithium iron phosphate), as follows:

Learn more -

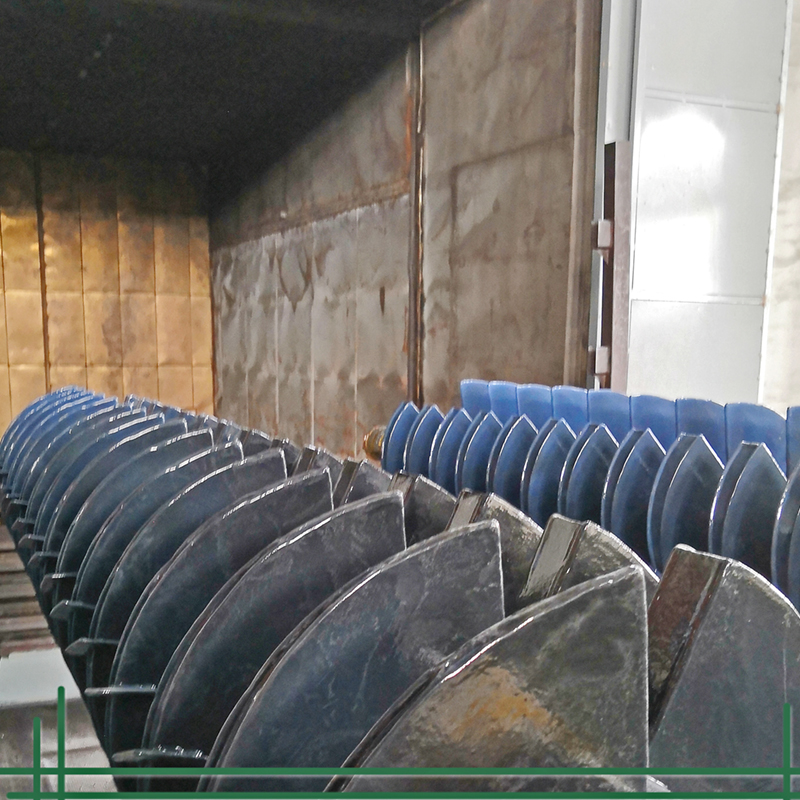

What are the application industries of agitator spraying

The core of agitator spraying is to enhance the corrosion resistance, wear resistance, and anti sticking performance of the agitator through surface coating. The application industry is concentrated in fields that require agitation media (liquids, powders, slurries) and have requirements for equipment loss or medium purity.

Learn more -

What are the characteristics of reactor spraying

The core characteristics of reactor spraying revolve around protective performance, adaptability, and process stability, aiming to improve the service life and adaptability of the reactor. 1. Excellent protective performance Form a dense coating that effectively resists corrosion from corrosive media such as acids, alkalis, salts, etc., and is suitable for corrosive working conditions in

Learn more -

What is the main purpose of spraying PTFE anti adhesive coating on the material bucket

The PTFE anti adhesive coating sprayed on the material bucket is mainly used for the following purposes: 1. Easy to clean: PTFE has good non adhesiveness, smooth coating surface, and almost no substance adheres. This makes the material bucket easier to clean after use, reducing the time and effort required for cleaning and improving work efficiency.

Learn more

CN

CN EN

EN

Service hotline:

Service hotline:

Wechat number:

Wechat number:

National Service Hotline

National Service Hotline

Service hotline:0512-69211270

Service hotline:0512-69211270

Company address:1188 CUIZHOU Road, Lili Town, Wujiang District, Suzhou

Company address:1188 CUIZHOU Road, Lili Town, Wujiang District, Suzhou

contacts:Deng Guangcai 13912602396

contacts:Deng Guangcai 13912602396

contacts:Long Yanqiao 15995489385

contacts:Long Yanqiao 15995489385

Add wechat

Add wechat

Contact us

Contact us

Telephone consultation

Telephone consultation